Forestry & Lumber Chain

Bison lumber chain series are very popular in North American for several years, we are the OEM factory for many big brands in forestry industry.

Our 81X Conveyor Chains and Welded Steel Chains have the strength, wear life, and dimensional accuracy to withstand severe impact and abrasion from wood chips, ash, and sawdust.

Today’s sawmills generally use one of three chains for their drop sorter: 81X, C2100H or 3939 chains. Each chain is fabricated with an attachment to push or carry finished boards to a sorting bin by size. Like every operation in a sawmill, the drop sorter has to run at peak performance at all times.

Sharp Top chain we determine the exact degree of tip sharpness to work best for each application, creating maximum grip with minimum penetration and tear out.

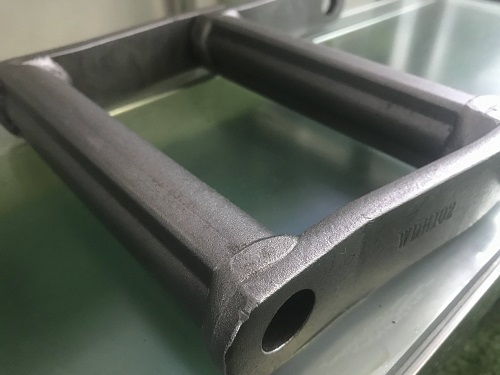

Welded steel mill and drag chain is available. Our mill chain is designed for strength, precision, wear resistance, and impact resistance. For example, have press-fit pins, which reduce the possibility of pin fidgeting and improve wear life. Pin holes are accurately punched and welds automatically applied for better consistency and increased reliability. Welded Steel Mill Chain operates in some of the most demanding applications. The inherent design provides high tensile and fatigue strength. This brute of a chain must withstand high shock loading, provide resistance to abrasive material and operate in extreme temperatures and climates.